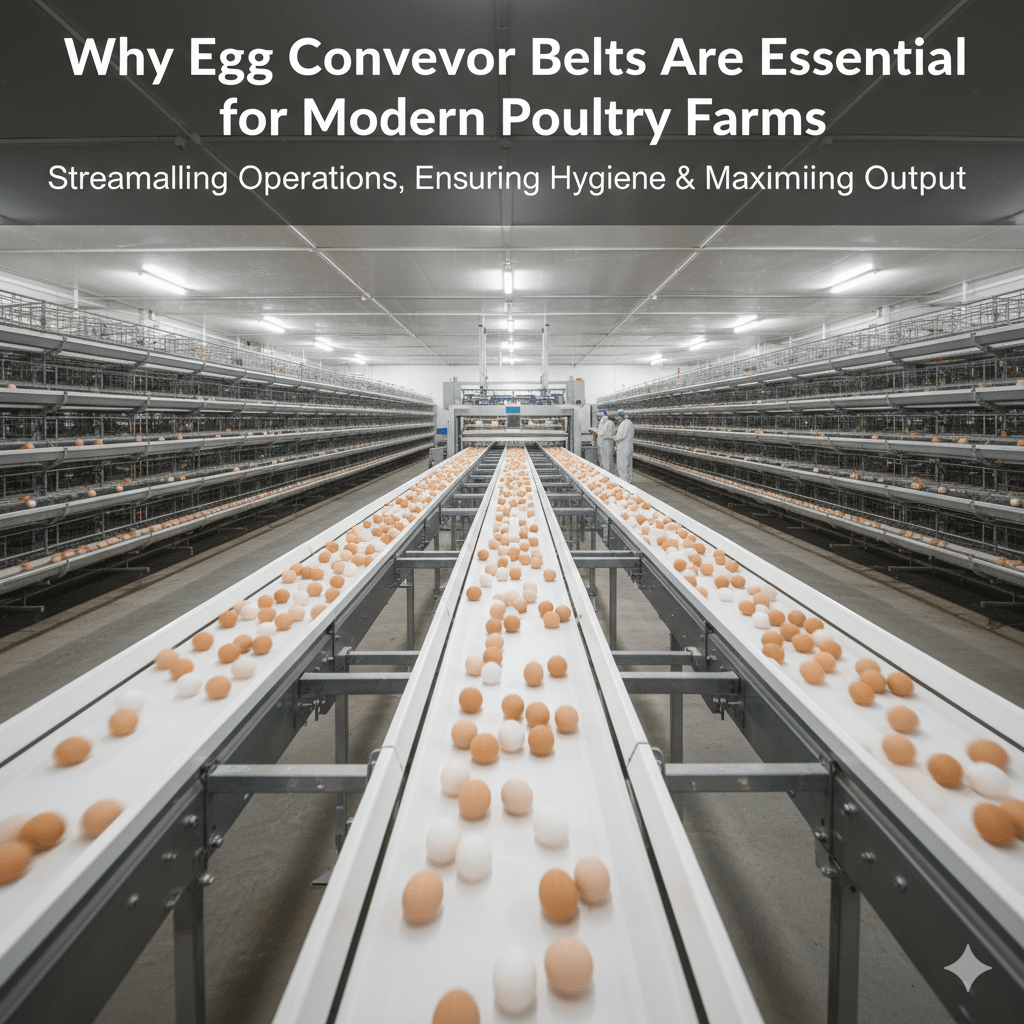

Take a tour of any high-performing poultry farm today, and you will surely hear the hum of machinery, and the soft roll of eggs gliding across belts. What you won’t hear? The chaos of manual handling, the clatter of broken shells, or the sighs of overworked laborers trying to keep up with thousands of laying hens. That’s because the modern poultry industry runs on something deceptively simple yet game-changing: egg conveyor belts.

You might think that a simple conveyor belt just moves eggs from point A to point B. But that’s the surface story. The real story is about how these belts transform an entire farm’s operation. And if you’re serious about running a scalable poultry setup, you can’t afford to ignore them.

I’ve seen enough poultry operations to say this confidently: those who invest in quality conveyor systems don’t just save time: they future-proof their farms. Because here’s the truth — eggs don’t stop coming. Once hens start laying, they do it with clockwork regularity. You might get a thousand eggs an hour or ten thousand a day, depending on your flock size. Either way, that’s a constant flow of fragile, high-value produce that needs to be moved, sorted, and stored: fast and safely.

This is where conveyor belts show their genius. They don’t just move eggs; they manage the entire flow of production. They’re designed to align perfectly with cages, collection trays, and graders, creating a smooth path from the laying house to the packing room. Every second saved, every cracked shell prevented, compounds into real money saved at scale.

You want efficiency? Conveyor belts are your quiet, mechanical workforce that never takes a break.

Here’s a hard truth: poultry farming margins are thin. Every efficiency tweak matters. When eggs are collected manually, you lose time, and time in farming is money disguised as labor costs, product loss, and fatigue. Conveyor systems flip that equation.

With automated egg collection belts, the process becomes streamlined. Eggs roll gently onto the belt as they’re laid, traveling at a controlled speed toward collection points. No human traffic between cages. No waiting for workers to gather trays. No bottlenecks. The result? Consistency. Predictability. Flow.

I’ve seen farms reduce daily egg collection time by nearly 70% after switching to belt systems. That’s not convenience; that’s operational leverage. It frees your staff for higher-value tasks, like maintenance, or quality control. That’s how you scale without adding chaos.

Let’s talk about what breaks a farmer’s heart literally. Broken eggs. Hairline cracks, fractures, losses that look small until you tally them up over a month. Each damaged egg represents lost revenue, wasted feed, and reduced profitability. The fix? Precision handling.

Conveyor belts built for egg transport are engineered with materials that balance grip and softness. They cradle the eggs rather than push them. The belts’ smooth, flexible design absorbs vibration and minimizes impact, keeping the delicate shells intact through the entire journey.

And it’s not just about cushioning. It’s about control. The belt’s consistent speed prevents pile-ups and collisions. Eggs move in an organized stream, each with its own space: no chaos, no collisions, no bruising. The result? Fewer breakages, better grades, and higher customer satisfaction.

I’ve seen farms cut egg damage rates from 8% down to less than 1% after installing proper belt systems. That’s not a small tweak; that’s the difference between surviving and thriving.

One of the smartest things about modern egg conveyor belts is how seamlessly they integrate into virtually any poultry setup. You don’t need to overhaul your entire infrastructure to make them work. Whether your farm runs on multitiered cages, free-range layouts, or automated packing systems, the right belt system can be tailored to fit your operation like a glove.

And let me be clear; this isn’t about buying flashy tech for the sake of it. It’s about functional integration. Good conveyor belts sync with existing machinery, grading systems, and packing lines without creating bottlenecks. You can automate one stage at a time: start with egg collection, then link it to the grading line, then to packaging. Gradual scaling is entirely doable.

I’ve worked with farms that started small, integrating belts only on one row of houses. Within a year, they extended the system across the facility. The difference in productivity and morale was night and day. Automation doesn’t have to feel mechanical; it can feel liberating when it’s built around your rhythm.

Agriculture is evolving. Labour scarcity is very much real, and reliable labour is in more limited supply. Conveyor belts aren't about replacing people, but empowering them. When your labor force isn't tied up collecting eggs by hand, your crew can do more important things - such as monitor flock health, maintain equipment or hygiene protocols.

It is a fundamental reduction of repetitive "monkey" work. The system takes on the manual labour, whilst your labour force have important work on their brain. That is how you build a smarter farm, not just a bigger farm. And conveyor belt systems mean better working conditions for the workforce as well.

Now, let’s get real: hygiene can make you entire operation messy if neglected. Eggs collected manually are handled by hands that may be contaminated. They are also exposed to many other surfaces compared to an automated layout. Conveyor belts reduce this contamination risk by a large margin since, the eggs are transferred directly from the laying area to the collection point without unnecessary human contact.

Cleaner handling equals higher biosecurity. That’s non-negotiable in today’s world of disease control and regulatory scrutiny. Conveyor systems also make cleaning easier as modern designs come with removable sections and smooth surfaces that resist buildup. The whole setup stays cleaner, safer, and far more compliant.

And if you’re exporting or supplying premium markets? You already know how strict quality standards can be. A belt system helps you meet them consistently: every egg, every day.

Here’s the part most people overlook: conveyor systems aren’t just mechanical tools anymore. The newest models integrate with data systems. They track all sorts of metrics like flow rates, and log production counts. Even the risk of malfunction is reduced as the system detects jams, immediately reducing downtime.

These data systems have redefined the efficiency of an egg production facility. You can spot inefficiencies before they become problems. Moreover data-backed decision making can take productivity to new heights. It’s the foundation of precision poultry management.

Ultimately, egg conveyor belts are not an option but a necessity for poultry farms that plan to remain competitive in the current environment. They diminish waste, protect your product, and simplify your daily processes.

I have witnessed the benefits firsthand of farms that integrate them into their operations - more efficient production, less loss, smoother workflow, and a more profitable operation. And just as clearly, I have seen the consequences of farms that do not integrate them - time spent waiting, more breakage, and an exhausted workforce.

So, if you are currently still gathering eggs by hand, my advice to you is to stop thinking of automation as a luxury. It will be your competitive advantage, your barrier against negative inefficiencies, and your route to sustainable growth.

Because in the landscape of modern poultry farming, speed is not the enemy, inefficiency is. And, the egg conveyor belt is your best tool to win that battle. One perfect egg at a time.