One of the most generic jobs in poultry farming is egg collection. The manual collection method involves workers visiting chicken houses several times a day to pick eggs by hand. This is very time- and labor-intensive.

The egg collection belt system mechanizes this crucial process and enables modern poultry farms to process their daily eggs. Knowing how these systems operate and their benefits will enable the operators of these farms to make informed choices regarding upgrading their farms.

Basic Components

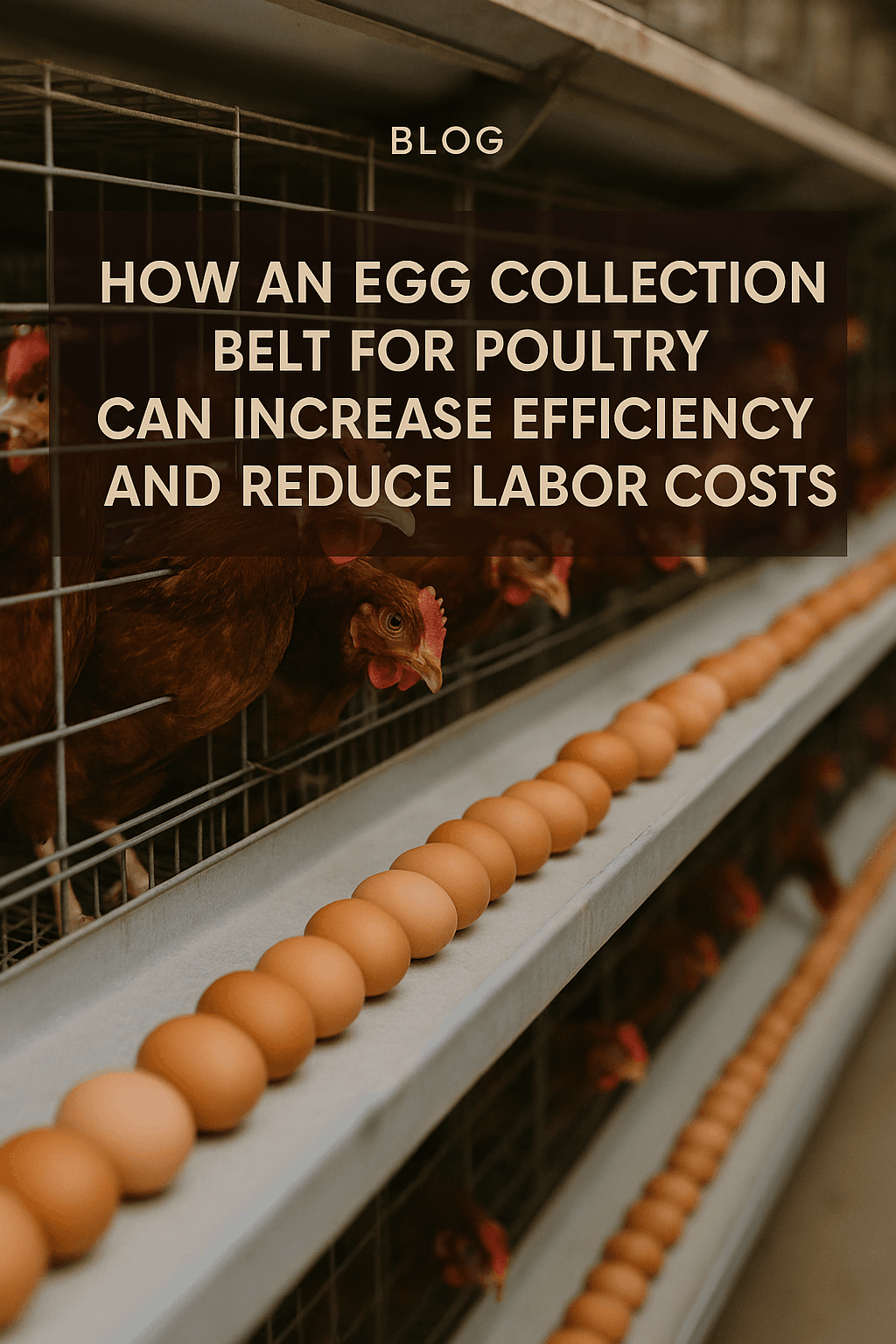

An egg collection belt is a conveyor belt placed under rows of cages or nesting boxes. The belt is long enough to run the length of the chicken house, where it mounts to receive eggs as hens lay. Eggs are slowly dropped onto the moving belt and conveyed to a collection point.

That system comprises the belt material, drive motors, support frames, and control systems. Materials used in belts are normally best food-safe plastic or rubber that will not harm eggs. Slow, steady belt speeds prevent egg breakage.

How It Works

When a hen lays an egg, it falls off the cage or nest and onto the belt below. The angled cage floor then channels eggs respectively to the collection system. The belt removes eggs from the laying section, preventing a hen from pecking or crushing them.

The eggs move on the belt to a collection point where the workers collect them, or the workers yield to automated packing. The constant rotation implies that eggs have the shortest time in the chicken house.

Eradication of Manual Collection Rounds

The conventional method of egg collection requires staff to walk between all rows of cages several times a day. In large outlays that contain thousands of hens, this consumes hours. The employees should select each egg carefully and place it in a collection cart or basket.

Egg collection belts remove these man-intensive rounds. Laborers have designated collection points rather than walking miles through chicken houses. A single individual can track the arrival of eggs from hundreds or thousands of hens. The saved time can be used by staff to perform other farm management activities.

Reducing Physical Strain

Manual egg picking entails repetitive bending, reaching, and carrying. Thousands of eggs are processed per day by workers, which is the cause of back strain and fatigue. The work is physically demanding and may result in long-term injuries.

Belt systems deliver eggs to workers at a comfortable working height. Employees do not have to walk and bend frequently. This makes the job less demanding, with the ergonomic enhancement reducing physical strain. The levels of worker satisfaction tend to rise, and the risk of injury reduces.

Faster Processing

Hand-collected eggs are formed in carts or baskets and then transported to processing areas. This creates batches that must be delivered periodically. It involves numerous handling stages between the cage and the final packaging.

The eggs are delivered to the processing areas by collection belts. Such continuous flow enables downstream operations to be more effective. The grading, washing, and packing process will not require completion of collection rounds before it can proceed. The facilitated workflow enhances the facilities' overall throughput.

Minimizing Egg Damage

Manual collection applies to each egg. Some breakage is experienced despite that. Employees working in overcrowded chicken houses can also strike collection containers with buildings. Broken eggs symbolize lost revenue and wasted feed.

Belt systems are not rough, and the human touch on the eggs is minimal. Eggs do not move violently as they do during manual transportation. The collection belts installed in farms usually reduce the breakage rates by a large margin. Increased egg survival leads to better profitability.

Cleanliness Maintenance

The eggs in the cages or nest boxes may get dirty with their droppings or broken eggs. Manual picking is routine, but an egg is stuck in the laying spaces. The longer the time spent in contamination, the greater the risk.

Eggs are collected by collection belts throughout the day. Eggs do not take too long to be in the chicken house environment. Such minimized exposure makes eggs cleaner and decreases bacterial contamination. Cleaner eggs need less washing and have better quality.

The Advantages of Temperature Control

The quality of eggs reduces when eggs are kept at high temperatures. Chicken houses may get hot, particularly during summer. Manual collection refers to eggs lying in warm conditions until they are collected during the collection rounds.

Belt systems are used to transport eggs to processing or cooler collections quickly. Internal egg quality is maintained through rapid evacuation of the chicken house. This thermostat helps preserve it and prolong its shelf life.

First Investment Factors

The Egg collection belt systems involve an initial capital investment. Prices vary depending on the size of the chicken houses, the cage structure, and the complexity of the system. Small holdings will be at a disadvantage, and those with large operations enjoy economies of scale.

The investment, however, usually recovers in a few years through savings in labor costs. Lower breakage and better egg quality also contribute to the return. Belt systems are considered infrastructure by many farm operators rather than optional equipment.

Ongoing Labor Cost Savings

Labor is one of the highest costs in egg production. With 50 to 70 percent labor saving on egg collection activities, collection belt systems can shorten the time required for the job. Savings are quick in cases where large farms have several collection workers.

Fewer labor requirements would entail lower payroll costs, benefits fees, and management overhead. The savings accumulate over the years. The net savings are large even when the belt maintenance and energy costs are factored in.

Productivity Gains

The workers will have more time to do high-value things as their time is no longer spent on manual collection. They can concentrate on the health status of flocks, facility care, and the quality. This re-distribution of labor enhances all-around farm productivity.

Efficient operations can control larger flocks without a proportional increase in staff. This has made it scalable to expand the farms without huge increases in labor costs. The productivity changes are not only in egg collection but also across the whole operation.

Egg collection belt systems have changed the way poultry is conducted by automating the egg collection process, which was previously labor-intensive. Automated egg collection is an efficient, consistent, and scalable method for modern poultry farms, regardless of size; thus, belt systems are an indispensable part of competitive egg production facilities.